Knoxville Residents - Learn Lean Six Sigma’s History Here

Contact Us

It can be difficult to go over the Lean Six Sigma History, as many believe it is about Lean in the 40s and Six Sigma in the 80s. Others, well, don’t know as much of the methodology’s history, but this is why we are here to leave the essentials—and a bit more—clear. Lean Six Sigma Curriculum for Knoxville High School Students of Tennessee is a company that specializes in the methodology and understands every part of it, from its inception till today.

You must first understand that this methodology was designed to help companies prioritize customers and improve earnings. It incorporated principles and structures of two major methodologies: Six Sigma and Lean—the ones we referred to earlier.

The methodology can reduce costs and eliminate waste if done correctly. It is important to keep quality and performance in mind throughout the entire process. Due to all these factors, the method has proven to be a great addition to ensuring customers are happy while still improving results and reducing costs.

However, there’s something we must leave clear, so you understand how all this originated: LSS is more than just a combination. Lean Six Sigma improves process and quality, and although the essentials come from Lean and 6 Sigma, it adds more value. Also, other methodologies—Japanese ones—influenced it.

Many believe LSS is Japanese because of the Kaizen method developed in Japan. This helped improve Japan’s industries, particularly manufacturing. It also encouraged thinking about the customer and reduced costs. This resulted in increased production and manufacturing.

No matter how you look at it, it feels quite LSS when compared and put together. However, LSS is more of an “answer” to compete with those Japanese companies achieving better results than those in America back in the 80s.

Lean & Six Sigma Origins

Six Sigma and Lean are both well-known concepts that have been around for many decades, and we need to study them before jumping to the conclusion of LSS and Kaizen.

Lean was invented by Toyota in the 40s to reduce non-value-adding activities.

Lean believes that employees should actively participate in organizational change to foster excellence and that continuous learning and improvement are two of the most important pillars to ensure everyone is happy, get the desired results, and maximize all resources.

It was created from the foundations of Toyota Production Systems (TPS), which Japanese Taiichi Okno founded. Lean was born using Henry Ford’s innovations and Business Process Redesign specifically.

This is the method based on the information provided so far and what summarizes most of its functionality:

- Lean begins with understanding the customer’s added value and how to satisfy it.

- Both the value stream and how processes are performed should be mapped.

- Later, it is required to identify the waste flow. The data is then collected to reveal waste and share. This is the first step toward improving the process.

- Next, Lean is the process of setting up the system in a way that customers can request it, and it delivers it to them when they are ready.

- Employees will be able to identify areas where they can improve and work together to fix the issues making the step slower or making the business invest more resources.

- This allows for process-wide thinking and for everyone to be focused on the customer’s requirements efficiently and effectively.

Lean is based on all the above, but Six Sigma is more data-driven. Motorola developed the method, and General Electric used it successfully in the 80s.

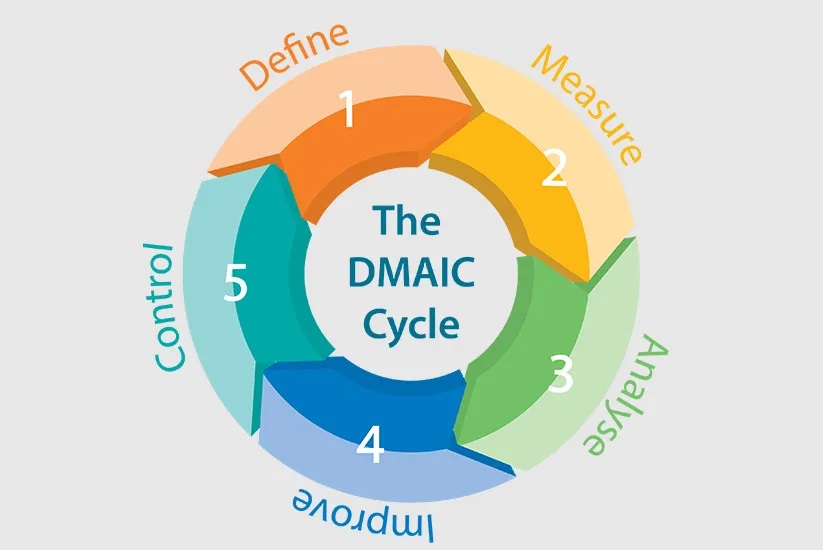

Six Sigma’s structure is centered around the DMAIC option. This is useful in manufacturing but also in other industries to automate processes and reduce waste while improving cycles and processes as the structure is: Define, Measure, Analyze, Improve, Control.

How Lean Six Sigma Originated in the USA

As Lean and 6 Sigma were performing well as individual methodologies, companies came up with the idea of combining them while still adding more elements that would be more focused on the main goals of continuous improvement and waste reduction.

Due to Japanese companies in the 80s and how the Kaizen and other methodologies were improving their products and satisfaction, American companies also had to work around their own methods.

This is how LSS allowed—and continues to allow—American companies to compete with Japanese manufacturers as the principles are similar and results could be associated, but with slightly different approaches in processes and their improvement.

This addition provided valuable insights and improved efficiency for the industry. This combination allowed for growth without compromising customer services in most USA companies as well.

Today, the methodology has been introduced to more than products. Industries like healthcare and education see how they can reduce time and resources, so they are able to improve their systems.

This is why at Lean Six Sigma Curriculum Pros of Knoxville, we are so fixed on providing anyone in need of the methodology or trying to utilize it with all the training and certification needed for it.

Contact us, and we will provide guidance and all solutions.